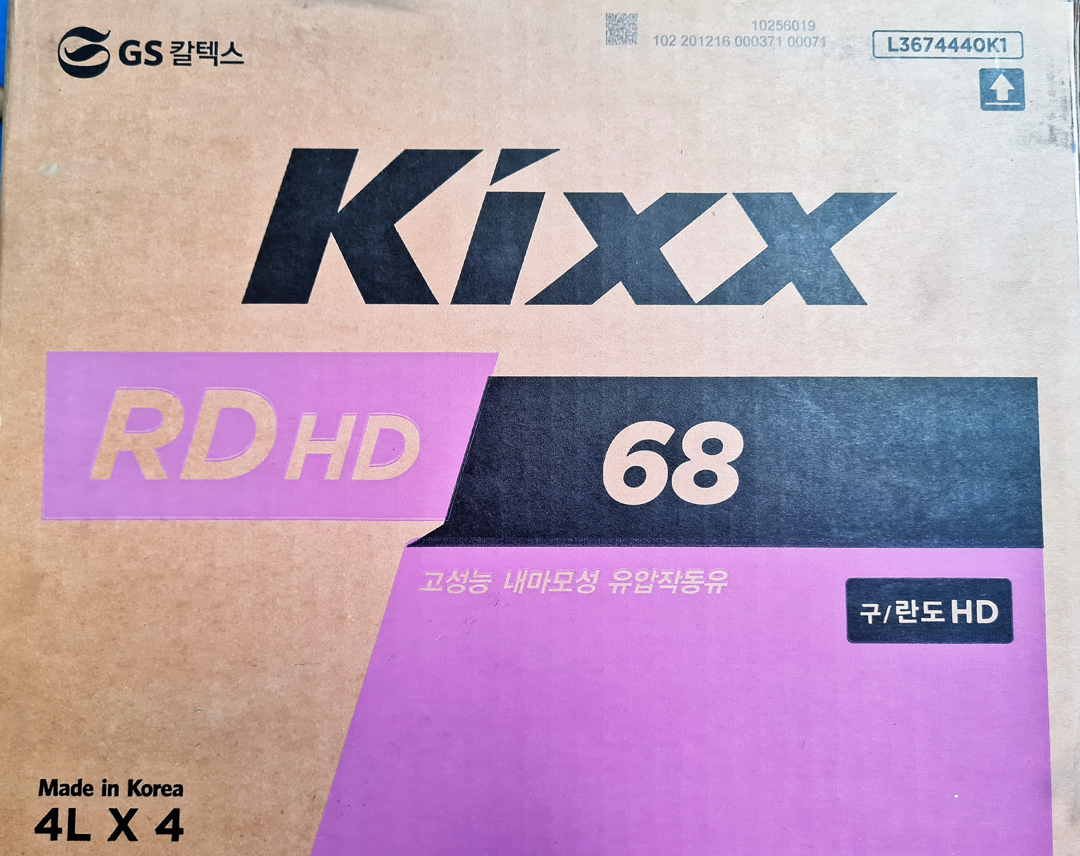

Application

All hydraulic equipment recommended by the machine manufacturer for use with anti-wear hydraulic fluids, pumps, universal circulating fluids, and transmissions operating under light loads.

Plastic injection molding machines.

Hydraulics used in applications such as forklifts, aerial lifts, etc.

Industrial hydraulic systems.

Performance standards

• ISO 11158 HM(VG 22, 32, 46, 68, 100, 150)

• ASTM D6158(VG 22, 32, 46, 68, 100, 150)

• DIN 51524 Part 2 HLP(VG 22, 32, 46, 68, 100, 150)

• GB 11118.1-2011, L-HM(VG 22, 32, 46, 68, 100, 150)

• Bosch Rexroth RDE 90220(VG 22)/RDE 90235(VG 32 ,46, 68)

• GM Hydraulic Anti-Wear(VG 22, 32, 46, 68)

• SAE MS 1004 HM(VG 22, 32, 46, 68, 100)

• AIST 126, 127(VG 32,46,68,)

• Parker Denison TP30560 HF-0, HF-1, HF-2(VG 32, 46, 68)

• Fives Cincinnati Machine P68(VG 32)/P70(VG 46)/P69(VG 68)

• JCMAS P041 HK Normal Temperature(VG 32, 46)

• Eaton E-FDGN-TB002-E(VG 32, 46)

• Eaton M-2950-S/Vickers I-286-S3(VG 68)

• JCMAS P041 HK Normal Temperature(VG 32, 47

Customer benefits

Excellent anti-wear performance helps prevent damage and increase the durability of lubricated components.

Provides protection against rust and corrosion for machine parts.

Minimizes foaming and emulsification caused by water or contaminants.

Prevents sludge formation and keeps the system clean during operation.

Highly compatible with seals and metal materials such as copper and zinc.

Suitable for systems requiring oil cleanliness levels of NAS Class 7 or higher.

Main characteristics

ISO Viscosity Grade: 68

Density @15°C: 0.8666

Flash Point (°C): 235

Pour Point (°C): -27

Kinematic Viscosity (cSt) @40°C: 67.4

Kinematic Viscosity (cSt) @100°C: 9.04

Viscosity Index: 109

Copper Corrosion Test: Pass